cnc machine coolants Most machine manufacturers provide explicit instructions on the type of coolant their machine requires. For instance, manufacturers of . See more Finally received the metal chassis for my wltoys a959b build. I started to assemble it all but I did end up running into a couple of problems which I go over.

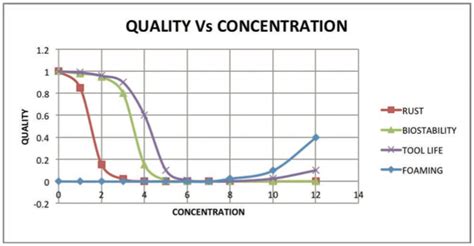

0 · machine coolant concentration chart

1 · coolant tank for cnc machine

2 · coolant system for milling machine

3 · coolant mixers for cnc equipment

4 · coolant concentration for cnc machines

5 · cnc machine coolant suppliers

6 · best semi synthetic machine coolant

7 · best coolant for cnc machine

Visit our online shop and get your hands on the best gear and apparel for your .

machine coolant concentration chart

The terms “coolant” and “lubricant” are often used interchangeably, but not all coolants are lubricants. For example, compressed air works as a coolant but has no use as a lubricant. No matter what type of CNC machining you do, CNC coolants play a Critical Role They help increase tool life and offer a better . See moreUsing water alone as a coolant is never a good idea since it’s the additives in the fluid that prevent damaging rust and corrosion. Typically, most CNC machine tools use one of the following types of coolant classified as follows: See moreUsing the correct coolant for the material and type of machining results in higher production efficiency and sustained high-quality products. Recommendations vary according to the manufacturer, but for a general idea of different coolants used for other materials and . See more

Most machine manufacturers provide explicit instructions on the type of coolant their machine requires. For instance, manufacturers of . See moreApplying a water-soluble cutting fluid is as vital as the type you use. Most CNC lathes and machining centers come with through-the-tool coolant capability, and it makes sense to use it, even if you must buy new tool holders. If your machine tool can use high-pressure . See more

metal fabrication bismarck nd

Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid consumption by reducing heat, friction, and debris. Oil-based, water-based, and synthetic . No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a .

Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid consumption by reducing heat, friction, and debris. Oil-based, water-based, and synthetic coolants offer varying benefits. Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant in CNC Machining Coolants for CNC machines help achieve optimal efficiency in a CNC shop. These coolants help reduce heat build-up, lubricate the cutting tool, and prevent discoloration and failure in machining processes such as CNC milling, turning, or drilling.

This article provides a comprehensive look at the types of CNC machine tool coolants available, their uses across industries, the importance of selecting the right coolant, and the factors to consider when choosing the best coolant for CNC machining. It’s important to choose the right type of CNC machining coolant based on your specific machining requirements. Consider factors such as cooling capacity, lubrication, corrosion prevention, and compatibility with the material being machined. The role of coolant in CNC machining is essential for maintaining tool life, achieving the desired surface finish, and ensuring overall process efficiency. This comprehensive guide will delve into the various types of coolants available, their benefits, and best practices for coolant selection and management in CNC machining. The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process.

CNC coolants, also referred to as cutting fluids, are specially formulated liquids essential for keeping your machining operations running smoothly. They mostly contain water, petroleum distillates, vegetable oils, and animal fats.

Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 . No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a . Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid consumption by reducing heat, friction, and debris. Oil-based, water-based, and synthetic coolants offer varying benefits. Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant in CNC Machining

Coolants for CNC machines help achieve optimal efficiency in a CNC shop. These coolants help reduce heat build-up, lubricate the cutting tool, and prevent discoloration and failure in machining processes such as CNC milling, turning, or drilling. This article provides a comprehensive look at the types of CNC machine tool coolants available, their uses across industries, the importance of selecting the right coolant, and the factors to consider when choosing the best coolant for CNC machining. It’s important to choose the right type of CNC machining coolant based on your specific machining requirements. Consider factors such as cooling capacity, lubrication, corrosion prevention, and compatibility with the material being machined.

The role of coolant in CNC machining is essential for maintaining tool life, achieving the desired surface finish, and ensuring overall process efficiency. This comprehensive guide will delve into the various types of coolants available, their benefits, and best practices for coolant selection and management in CNC machining. The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process.

coolant tank for cnc machine

coolant system for milling machine

CNC coolants, also referred to as cutting fluids, are specially formulated liquids essential for keeping your machining operations running smoothly. They mostly contain water, petroleum distillates, vegetable oils, and animal fats.

metal fabrication cape coral fl

Experience unparalleled carving, cutting, and shaping capabilities in woodworking and more. Elevate your craft with this advanced CNC system. Configure, Design and Cut projects in minutes - all on one, easy-to-use platform.

cnc machine coolants|coolant tank for cnc machine